| 1. Total steel-welded structure and stress elimination by vibration, high mechanical strength and strong rigidity |

| 2. Ram stroke hydraulic approaching downward, stable and reliable |

| 3. Mechanical stop and steel torsion bar to maintain synchronization and high precision |

| 4. Electrical/manual time adjustment and digital display for backgauge and ram stroke |

| 5. Compensation work table |

| 6. Nominal Force: 70t/1800 , Working speed: 0.6"/s |

CNC Bending Press Brake Main features

1. This machine tool is used to bend metal plates, It has high efficiency and bending precisions. When bending the different thicknesses of materials, You should select the different V-shapes to bend every kind of working piece.

2. The machine has a welding construction. It has enough strength and good rigidity.

3. Hydraulic transmission can avoid overload accidents that bend different thicknesses or the wrong selections of V-shapes.

4. The machine has the characteristics of stability and handling convenience. It has the actions of point, single and continuous strokes, and can keep the pressure.

5. Install the compensating construction to ensure higher bending precisions.

6. The users can order different kinds of dies and thus can bend different kinds of shapes of the working pieces.

7. If it equips the corresponding equipment, The machine can work as a puncher.

8. The machine is widely used in the fields of an airplane, automobiles, trains, shipyards, switch plants, communicating equipment lifting equipment, electrical, meter, and other light industries fields, and it has high efficiency.

Hydraulic Press Brake Bending

- Hydraulic Press Brake Bending has high labor productivity and high working accuracy for .

- Plate Press Brake adopts different shapes of upper and lower molds and can be bent into various shapes of workpieces.

- Plate Press Brake can bend the sheet one by one stroke of the slider. , After many times of bending, a workpiece with a more complicated shape can be obtained.

- When equipped with corresponding equipment, it can also be used for punching.

E21 Control System:

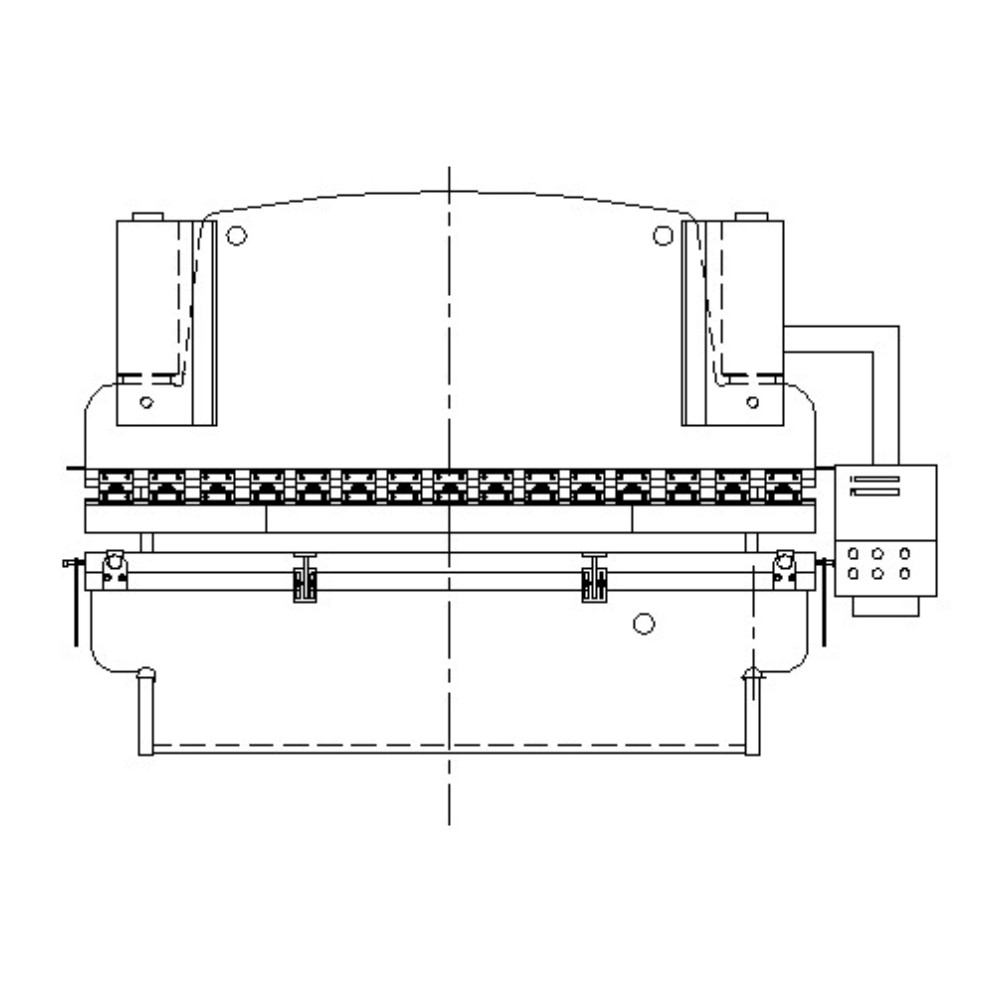

Main construction

Most machine parts are plate-welded parts, they have high strength, and good rigidity, are lightweight, And are transmitted by hydraulic. It mainly consists of the machine body, ram, adjusting construction of the mechanical stopper, synchrony-twist shaft, front-support or dies, electrical, etc.

- Hydraulic Motor BEIDER SIEMENS-China / Germany Tech

- Electrical Component SCHNEIDER / Germany Tech

- Hydraulic Pump YOUSHUN/OKDO China

- Hydraulic Valve BOSCH REXROTH Germany

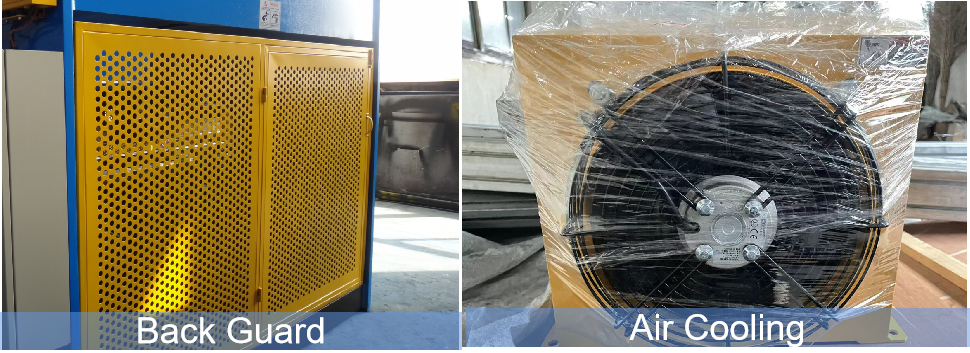

STANDARD COMPONENTS

OPTIONAL COMPONENTS

| Nominal Force | 70 Ton |

| Length of worktable | 70-55/64" (1800 mm) |

| length of walls | 56-11/16" (1440 mm) |

| Ram stroke | 4-23/32" (120 mm) |

| Throat depth | 13"-11/32" (300 mm) |

| Opening height | 13-25/64" (340 mm) |

| Distance of back gauge | 0-23-5/8" (0-600 mm) |

| Approaching speed | 3-35/64"/s (90mm/s) |

| Working speed | 19/32"/s (15mm/s) |

| Returning speed | 3-35/64"/s (90mm/s) |

| Dimension(LxWxH) | 70-55/64"x59-1/16"-88-37/64" (1800x1500x2250mm) |

| Main power | 7.5 kw |

| Net weight | 9921 lbs (4500kg) |