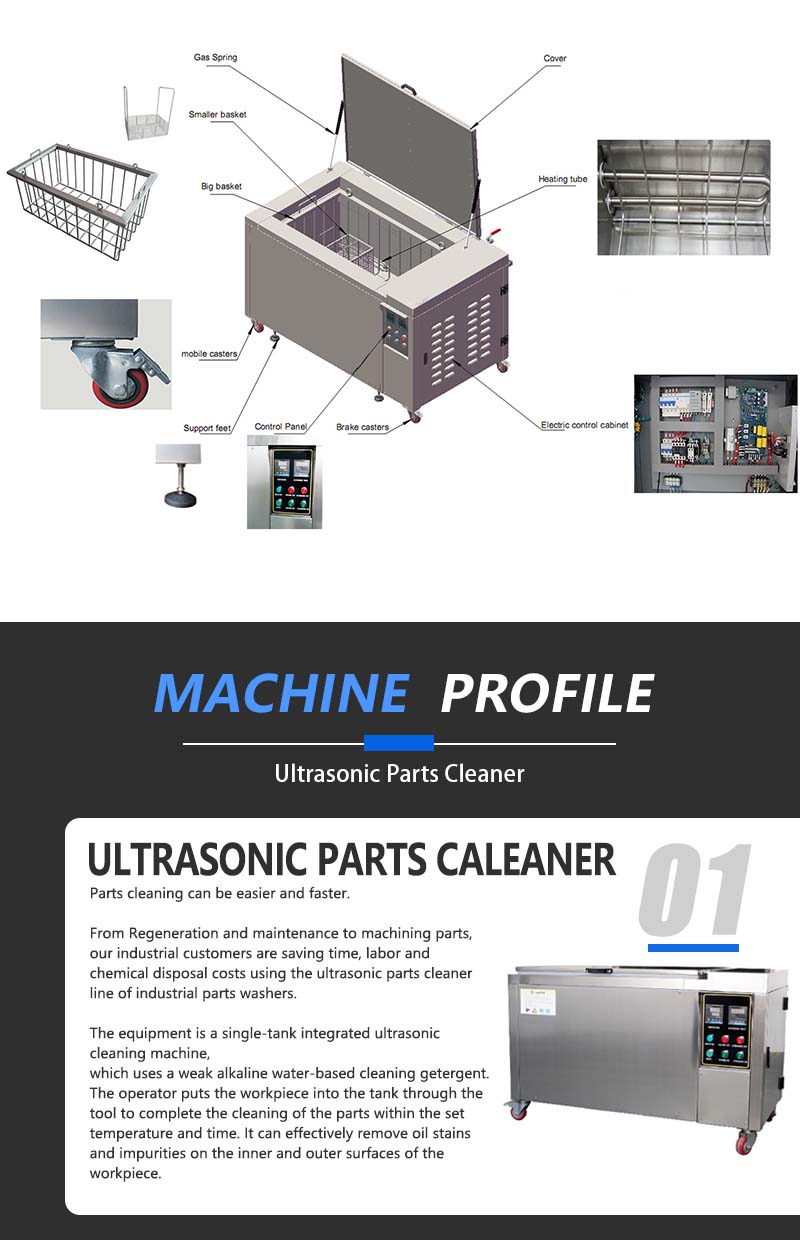

| 1. SUS304 Stainless Steel Tank -Ultrasonic cleaner’s tank is made of 2mm thickness SUS304 stainless steel;good corrosion resistance and heating resistance |

| 2.High power heating element - fast heating, saving heating time- we can adjust the heating water temperature up to 167ºF during use cleaner. |

| 3.28kHz frequency is stronger cleaning effect and suitbale for cleaning auto parts. |

| 4.Spigot for Easy Draining |

| 5.Digital temperature control |

| 6.Including Attachments: Sound proof lid,Power lead ,Mesh basket |

| 7.Casters for portability |

| 8.Digital timer-controlled ultrasound |

Description

ULTRASONIC CLEANER - cleaning machinery and manufacturing equipment, laboratory equipment, medical equipment, precision instruments, aerospace, ships, automobile maintenance and other industries play a very important role.

It cleans contaminants quickly and effectively and is compatible with aluminum and other materials commonly used in parts such as aluminum, stainless steel, Inconel, titanium, etc. Ultimately, our powerful and customizable ultrasonic systems provide eco-friendly, fast, precise and thorough cleaning that saves you time and money in the long run.

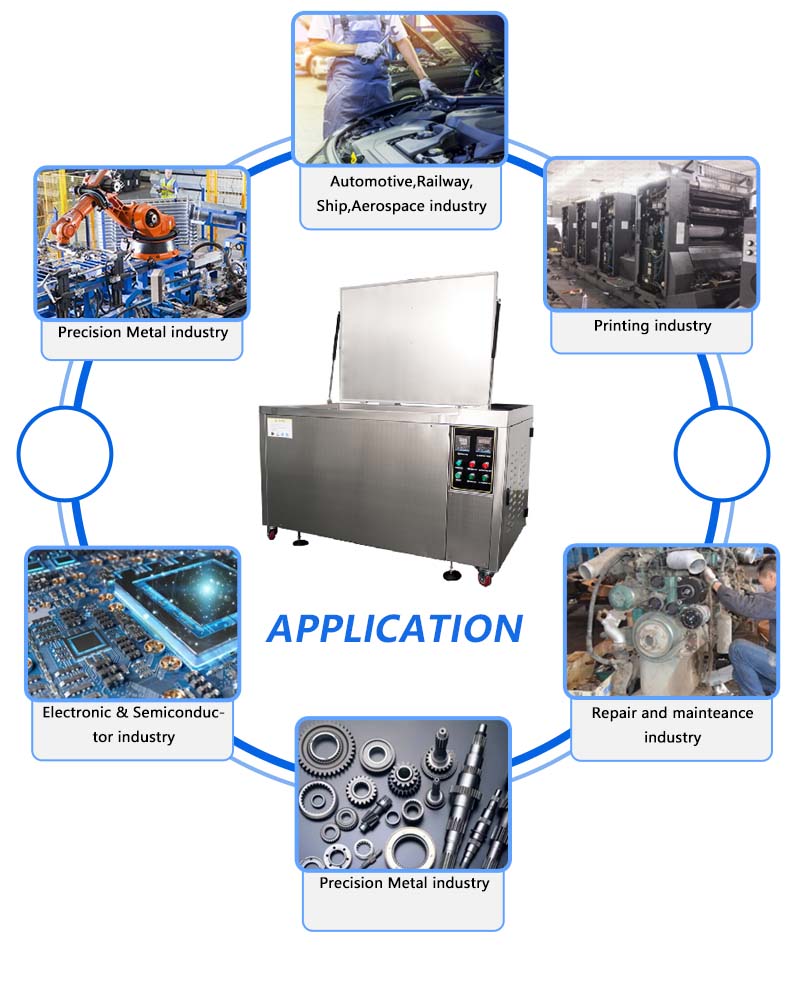

Application

- Automotive

- Aerospace industry

- Ship maintenance

- Repair and mainteance industry

- Printing industry

- Precision metal industry

- Electronic & semiconductor industry

NOTICES

1) The general working temperature of the ultrasonic cleaner is about 55 degrees (131ºF), and the long-term working temperature should not exceed 70 degrees(158ºF);

2) It is forbidden to turn on the ultrasonic and heating functions without adding liquid;

3) The parts need to be put into the cleaning tank for cleaning through the basket, and it cannot be directly put into the working tank for cleaning;

4) When the parts are placed and taken out of the cleaning tank, turn off the ultrasonic work first;

5) The choice of cleaning detergent should satisfy 7<=Ph<=13;

6)The moving device of the equipment is only used for the moving position of the tank body when it is vacant, and cannot be used to fill the liquid or clean the parts frequently.

Specification

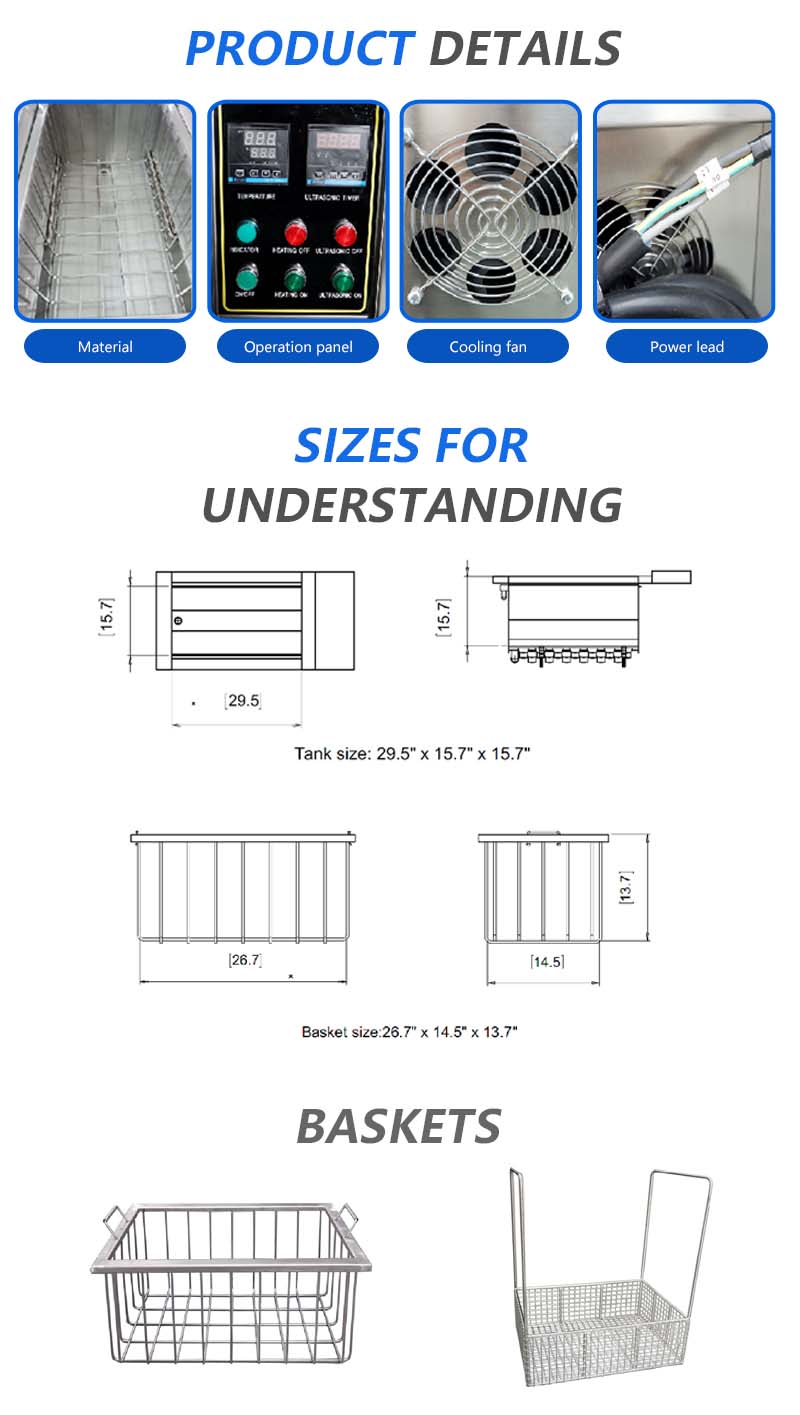

| Model | TS-2000 |

| Volume | 31gal |

| Dimension | 45.2" x 27.9" x 26.7" |

| Tank size | 29.5" x 15.7" x 15.7 " |

| Useful size of basket | 26.7" x 14.5" x 13.7" |

| Ultrasonic frequency | 28 kHz |

| Heating power | 6.6 kw |

| Ultrasonic power | 1100 w |

| Voltage supply | 220V/60Hz/3Phase |

| Basket Max load capacity | 80kgs / 176lbs |

PACKING INFORMATION

| Packing size | 50" x 30.3" x 33.8" |

| N.W. | 286lbs |

| G.W. | 440lbs |