About this product

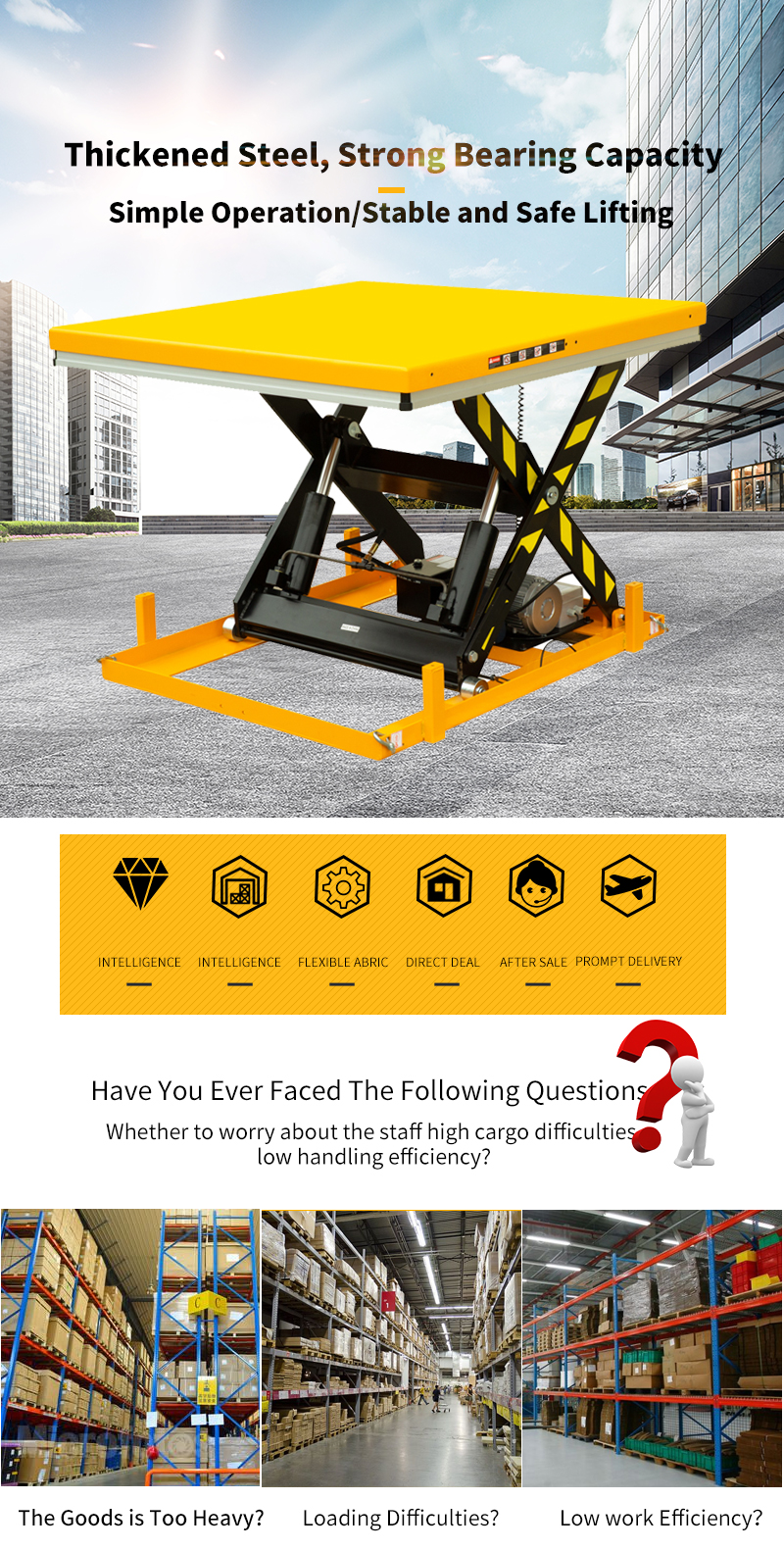

1. This Electric Hydraulic Stationary Scissor Lift Table can load 4400lbs cargo, the Platform Lowered Height: 7.9" Max lifting height: 40" Platform Sizes: 48"LX48"W.

2. High Strength Construction Steel and High Quality 2.2KW Motors to Ensure The Performance of The Electric Hydraulic Scissor Lift Table.

3. The Control type of this Electric Scissor Lift Table is Hand Operated.

4. 115V, 1 Phase Motor is Suitable for Industrial Voltage in the USA.

5. CE certificated

Powered Electric Hydraulic Stationary Scissor Lift Tables 4400lbs 48X48" Size Max Height 40"

Our heavy duty static scissor lift table is a hydraulic platform to raise and lower loads of 2200lbs,4400lbs, offering a convenient and flexible solution to the manual handling of goods. The large platform lift table is used within production lines as an ergonomic solution to support active working environments. The large platform lift table through its hydraulic scissor mechanism powered through a single-phase electrical supply; the operator can load goods or a pallet on to the lifting platform.

Production can be executed by raising the working load to the suitable height. In addition, the large platform lift table can be used in above-floor or in-pit applications so loads can be lifted with ease where you require them to be handled. The high quality powered stationary scissor lift table stands up to day-to-day working environments; allowing you to get on with the job in hand.

Why and Where to Use:

Ideal for handling bulky heavy materials. Maximize worker and machine productivity by hydraulically positioning work at just the right level. Raise or lower to feed or accumulate from machines or conveyor lines. Ideal for handling bulky or heavy materials. Raise load to desired position to prevent back injuries and reducing bending, caused by heavy-duty tasks like lifting and bending.

Widely used in automotive, container, mold manufacturing, wood processing, chemical canning and other industrial enterprises and production lines.

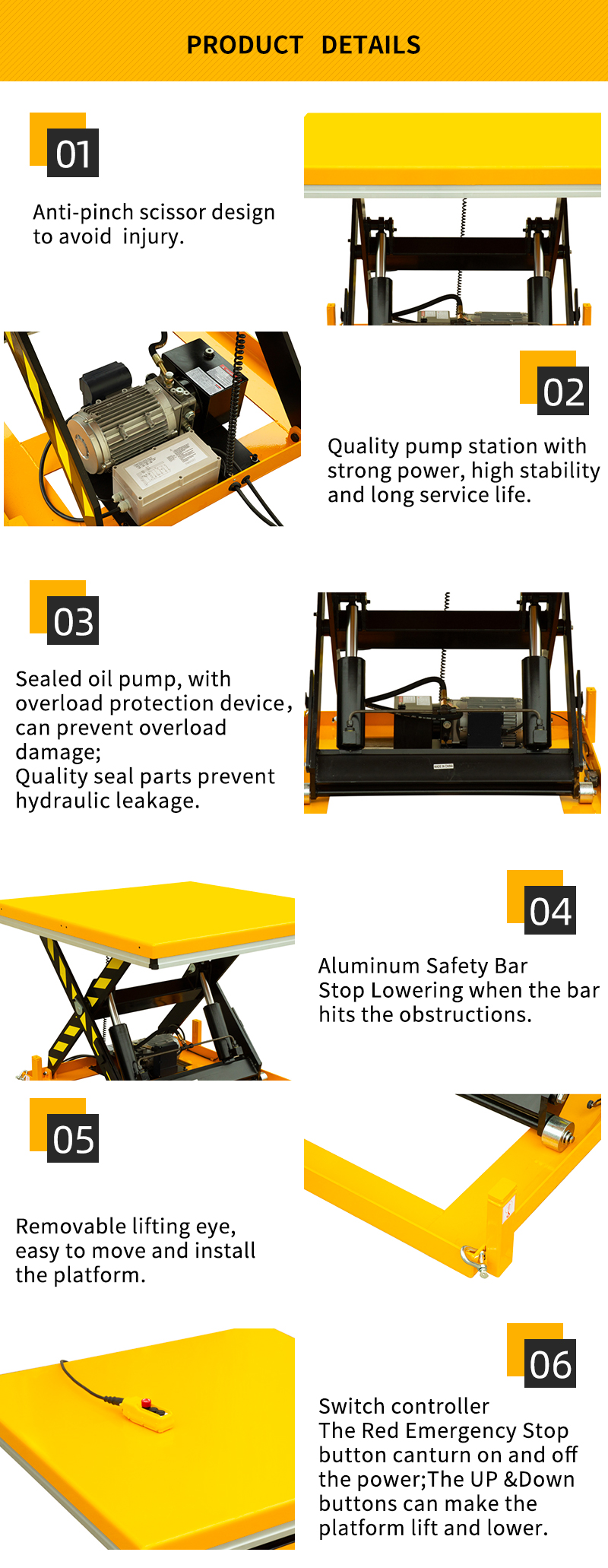

Standard Safety Features

1. Upper platform lifted with aluminum safety bar preventing descent on contact with obstructions.

2. Low-tention(24V) control box with up-down buttons.

3. Internal power pack equipped with relief valve against overloading and compensated flow valve for controlled lowering speed.

4. Heavy duty cylinders with drainage system and check valve to stop the lift table lowering in case of hose burst.

5. Safety clearance between scissors to prevent trapping during operation.

6. With anti-explosion valve

7. With Safety guard

8. Upper travel limit switch to stop table at maximum height to reduce motor wear

9. Product meet EN norm and ANSI/ASME safety standards.

Warning

1. Do not put foot or hand in scissors mechanism or through frame.

2. Use the lift table on flat and solid ground.

3. It is forbidden to operate the lift table while a person is under the table.

4. Do not adjust the safety valve of hydraulic power pack.

5. It is forbidden to operate the lift table even if there is small structure distortion.

6. Do not use in an explosive or flammable place.

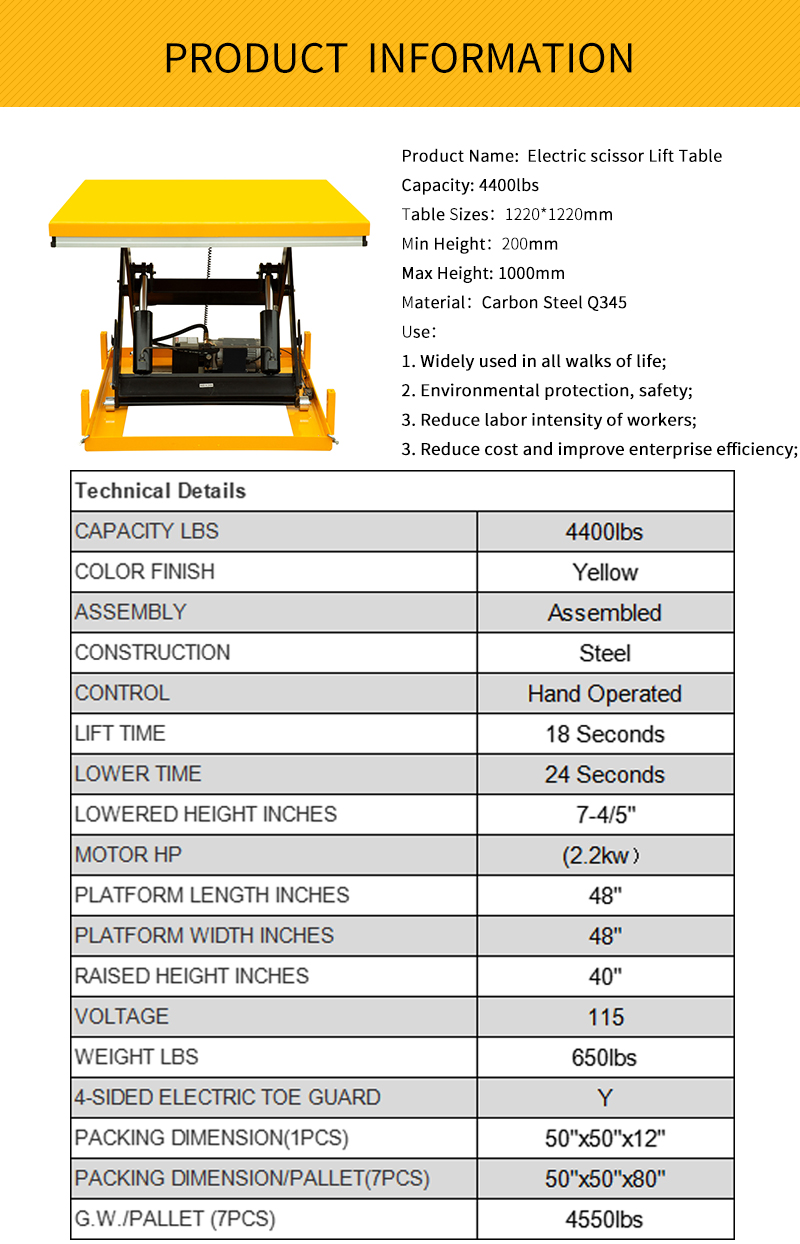

| Technical Details | |

| CAPACITY LBS | 4400lbs |

| COLOR FINISH | Yellow |

| ASSEMBLY | Assembled |

| CONSTRUCTION | Steel |

| CONTROL | Hand Operated |

| LIFT TIME | 18 Seconds |

| LOWER TIME | 24 Seconds |

| LOWERED HEIGHT INCHES | 7-4/5" |

| MOTOR | (2.2kw) |

| PLATFORM LENGTH INCHES | 48" |

| PLATFORM WIDTH INCHES | 48" |

| RAISED HEIGHT INCHES | 40" |

| VOLTAGE | 115 |

| WEIGHT LBS | 650lbs |

| 4-SIDED ELECTRIC TOE GUARD | Y |

| PACKING DIMENSION(1PCS) | 50"x50"x12" |

| PACKING DIMENSION/PALLET(7PCS) | 50"x50"x80" |

| G.W./PALLET (7PCS) | 4550lbs |

What Is a Scissor Lift?

Scissor lifts provide the most stable, dependable, and versatile method of lifting heavy loads. Because of their simplicity and few moving parts, maintenance-free bushings, and wide acceptance by customers, scissor tables provide many years of trouble free operation for relatively small capital investment. Scissor lift mechanisms are easily modified by narrowing, widening, combining or stacking to achieve an extremely wide array of configurations to effectively move loads of virtually any size or capacity to heights of 20 feet or more. Hydraulic scissor lifts are the most popular, versatile, and economical of all actuation styles.

What Is Lowered Height?

Lowered height is the height from the lift bottom to the top surface of the platform when measured in the fully collapsed position.

What Is Raised Height?

Raised height is the height from the lift bottom to the top surface of the platform when the lift is measured in the fully raised position.

What Is Travel?

Travel is the difference between Lowered Height and Raised Height.

What Is Lifting Capacity?

Lifting capacity is the weight of a centered load a lift can safely raise and lower without damage to the lift.

Can A Lift Be Safely Raised And Lowered With An Off-Centered Load?

Loads that have a center of gravity (CG) which is located outside the scissor leg set will contribute to excessive wear and shortened life of the lift – the further out from the edge of the legs, the sooner the lift will destroy itself. The load CG should always be located within 6 inches of the center line of the scissors in order to realize the full useful life of the lift.

What Does Edge/Side Load Mean?

Edge load and side load are static loads (not raised or lowered) that are placed directly on or near the end or side edges of a lift platform. Edge loads are important because lifts will deflect excessively when loaded this way, often resulting in permanent damage.

Is The Lift Surface Or Pit Mounted?

Most lifts can either be surface- or pit-mounted. Be aware pit mounting may require modification of the platform and/or added safety options.

Why Would I Pit Mount A Lift?

Pit mounted lifts allow the platform surface to rest at grade level. The most obvious benefit of having the platform at grade is the ability to roll on and off your lift platform.

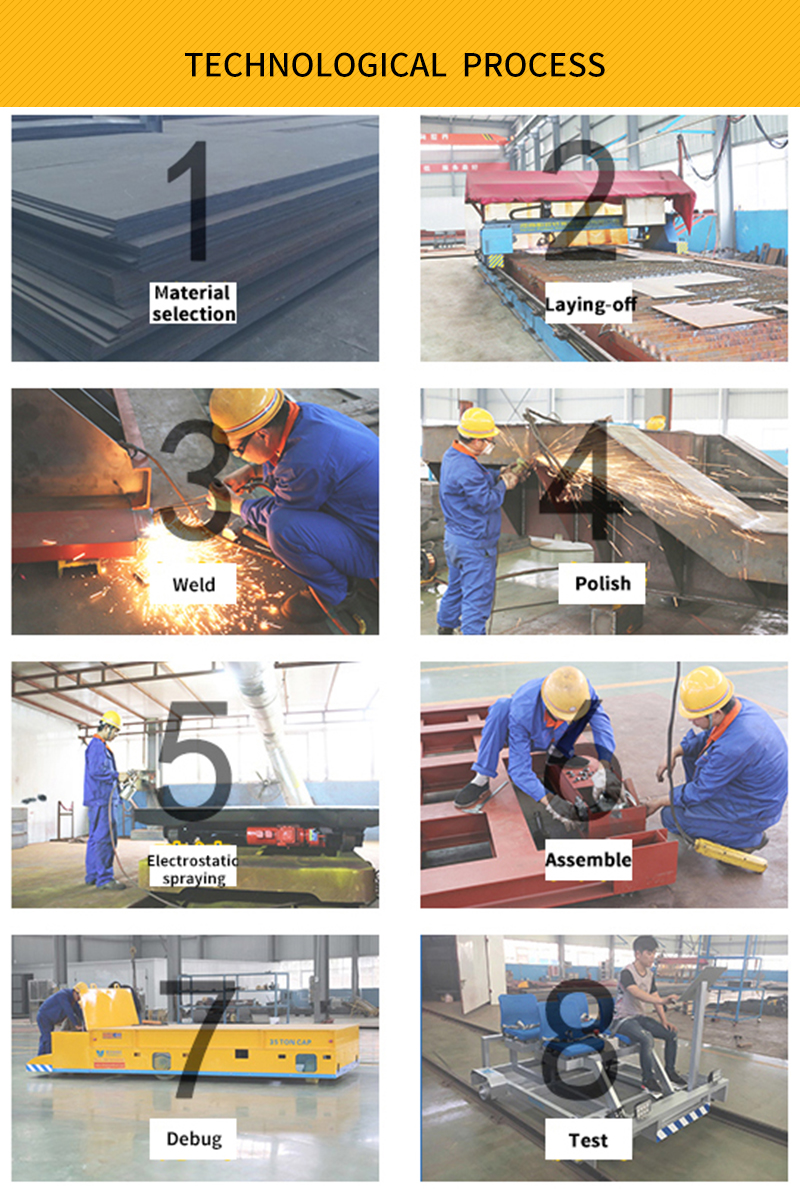

What about the quality of your Electric Stationary Loading Dock Scissor Cargo Lift table?

Our Electric Hydraulic Scissor Lift Tables are as thick as Southworth Hydraulic Scissor Lift Tables,Autoquip Scissor Lift table, Edmolift, Prestolifts. The motors are made of a first-tier brand-Swiss Bucher, and our Stationary Lift Tables are CE approved. We have five inspection steps before the Lifting Tables shipment:

1)Inspect the raw material in accordance with ISO9001;

2)Strict inspection in the whole production process;

3)Load limit test when assembling finished;

4)100% strict inspection of products before shipment;

5)If needed, inspection by buyer.

The actual load of the Heavy Duty Stationary Electric Hydraulic Scissor Lift Table exceeds the rated load, can it be lifted and used normally?

The bearing capacity of our heavy electric hydraulic lifting platform is designed in accordance with 120% safety factor. Occasionally, overload is used in a short time and the load is in the range of safety factor, which will not cause damage to the lifting platform. If the lift overload for a long time will damage the mechanical structure of the lift, resulting in irreversible deformation,there would also be serious security concerns. Therefore, the fixed electric hydraulic lifting platform is strictly prohibited to use overload.

Can the electric hydraulic lifting platform be connected to the PLC of the production line?

Yes, our electric hydraulic lift platform can be used alone, but also the lifting platform control line access to PLC, PLC directly control the lifting platform rise, fall and emergency stop.

What safety protection devices does the lifting platform have?

1)Upper platform lifted with aluminum safety bar preventing descent on contact with obstructions.

2)The fixed hydraulic electric lifting platform uses heavy duty cylinders and is equipped with relief valves and check valves to prevent the lifting platform from descending when the hose bursts.

3)There is a safety gap between the scissors of the lifting platform, which can effectively prevent the clamping injury in the process of operation.

Why can't the Power Hydraulic Scissor Lift Table rise to the highest position after using for a period of time?

If the Power Hydraulic Scissor Lift Table is found to rise less than the highest position in the process of use, the user needs to refuel in time to ensure the normal oil pressure. Generally speaking, the Power Hydraulic Scissor Lift Table should carry out an oil change within 3 to 6 months of purchase, and then add oil every six months. If the use frequency is high, the refueling cycle can be shortened. The hydraulic oil is #46 anti-wear hydraulic oil.

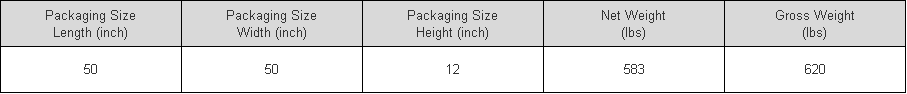

| Packaging Size Length (inch) | 50 |

| Packaging Size Width (inch) | 50 |

| Packaging Size Height (inch) | 12 |

| Net Weight (lbs) | 583 |

| Gross Weight (lbs) | 650 |