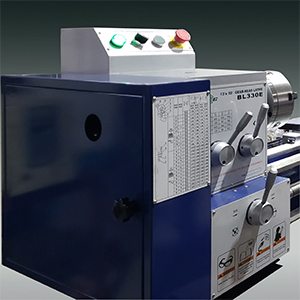

| 1. Metal gear drive head stock for quick change spindle speed |

| 2. All gears in headstock are hardened and precision ground |

| 3. Powerful 1.5 HP AC motor |

| 4. Milling Machine 5-2/5" wide two precision’V’- beds are hardened and ground |

| 5. Benchtop lathe 1.5" diameter spidnle bore with MT5 spindle taper |

| 6. Metal lathe 1.5" diameter spindle bore with MT5 spindle taper |

Be deploied 2 axis DRO

Toread the rate of feeding or machining

accurately,2 axis or 3 axis ditial read-out

areavailable. It is deploied with 2 or 3 axis

gratingscale and display in metric/inch

conversion

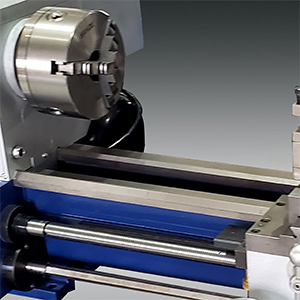

1.5" Spindle Bore

MT5 spindle nose taper with dig diameter 1-1/2" spindle bore and ground gears in head stock run in oil bath with lo noise.

Hardened two ‘V’ bed

MT5 spindle nose taper with dig diameter 1-1/2" spindle bore and ground gears in head stock run in oil bath with lo noise.

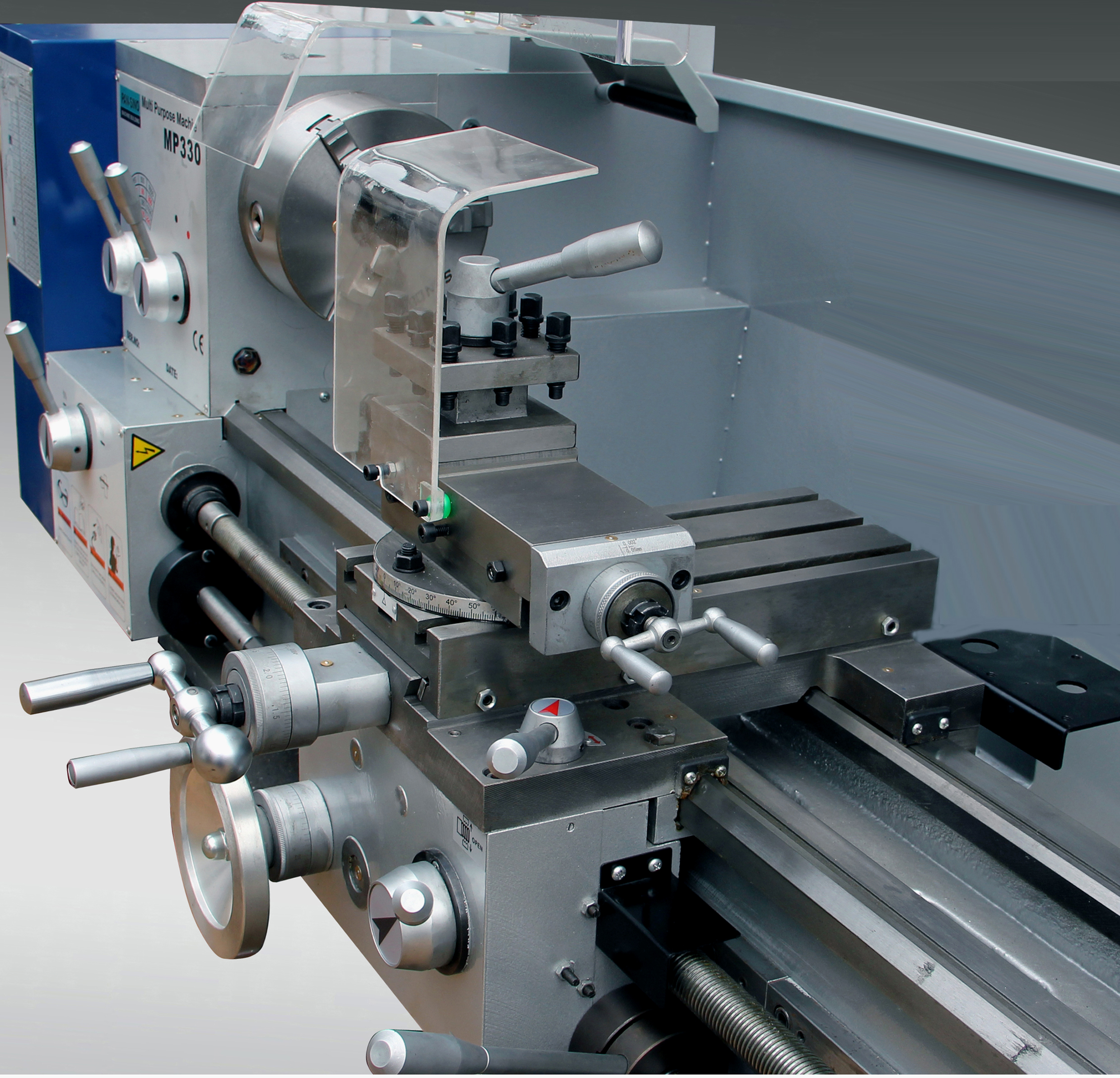

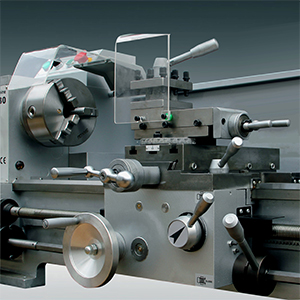

Featured carriage and apron

Full featured carriage and apron assemblies travel smoothly on finely finished bed, providing super accurate and finishes.

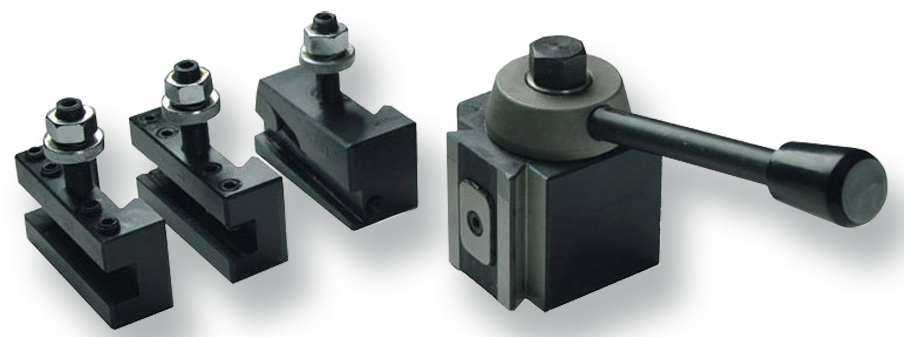

Profession compound assembly

T-slotted compound side with 4-stations tool-post, unique and safety handle easy to operate longitudinal and cross feeding.

Tailstock adjustment

Tail stock with V slide for lateral adjustment, adjustable offset by ± 5 mm for taper turning, sleeve and hand wheel.

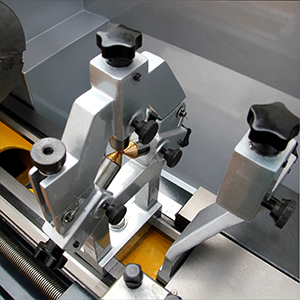

Steady & follow rest

Also includes fine-making steady rest and follow rest for assistant producing non-standard or long-thin work-piece and high accurate.

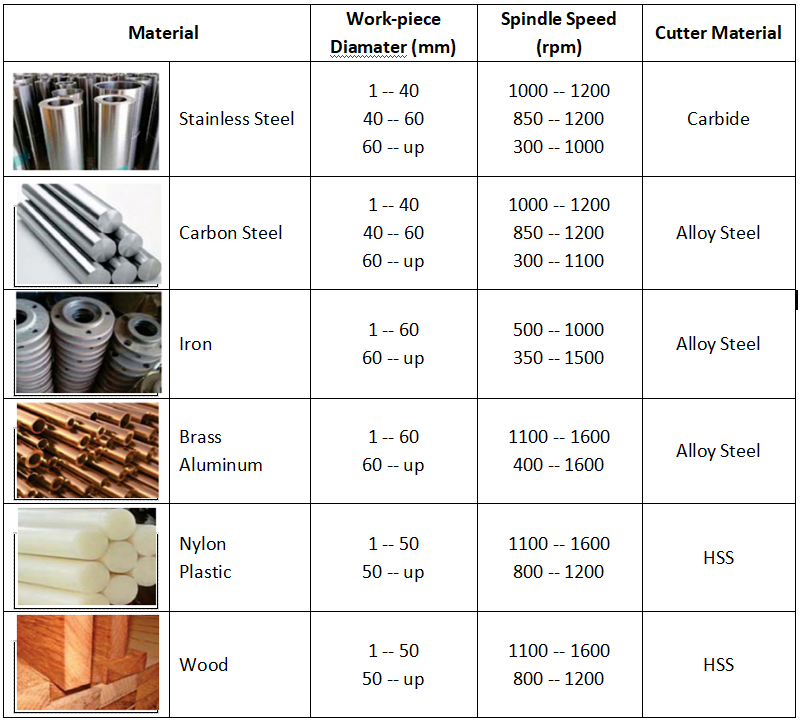

The list some rates of spindle speed while machining workpeice for reference only.

Standard Accessories Inludes

- Self-centering 3 jaw chuck with reverser jaw & key

- Dead center MT3

- Change gear

- Inner heaxgonal wrenches

- Open end wrenches

- Tool-post wrench

- Oil gun

- Screwdriver

Independent Four Jaw Chuck (optional accessories)

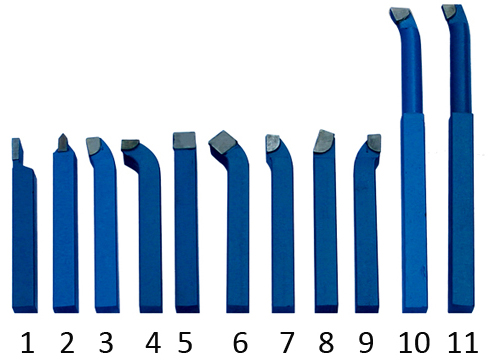

HSS Turning Tool (11pcs./kit (optional accessories)

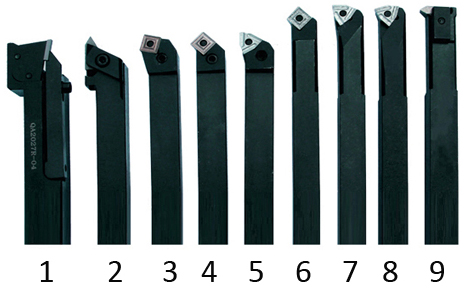

Carbide Insert Tool Holders (9pcs./kit) (optional accessories)

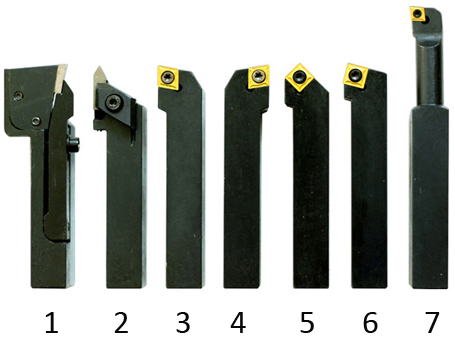

Ti Carbide Insert Tool Holders (7pcs./kit (optional accessories)

3-Axis Digital Read Out Displayer (optional accessories)

Piston Type Quick Change Tool Post (optional accessories)

| Max. Swing over Bed | 13" (330mm) |

| Max. Swing over Carriage | 8-21/32" (220mm) |

| Bed Width | 6-19/64" (160mm) |

| Distance between Centers | 29-1/2" (750mm) |

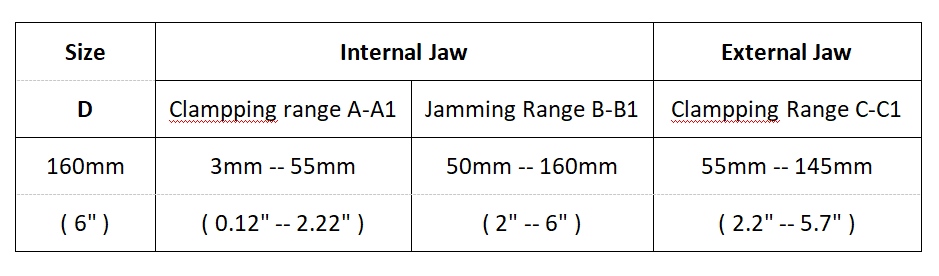

| Chuck | 6" 3-jaw manual chuck |

| Spindle Bore | 1-1/2" (38mm) |

| Spindle Taper | MT-5 |

| Spindle Motor | 1.5 hp (1.1 kW) |

| Number of Spindle Speeds | 12 |

| Range of Spindle Speeds | 60 - 1,800 rpm |

| Tailstock Quill Travel | 3-11/32" (85mm) |

| Tailstock Quill Diameter | 1-17/64" (32mm) |

| Tailstock Quill Taper | MT-3 |

| Tool Post Travel | 3-15/16" (100mm) |

| Cross Travel | 6-19/64" (160mm) |

| Longitudinal Travel | 26-49/64" (680mm) |

| Range of Cross Feed | 0.0018 - 0.0236 ipr (0.045 - 0.6 mm/r) |

| Range of Longitudinal Feed | 0.0039 - 0.059 ipr (0.1 - 1.5 mm/r) |

| Tool Size | 5/8" × 5/8" (16 × 16 mm) |

| Number of Inch Threads | 23 |

| Range of Inch Threads | 9 - 40 TPI |

| Number of Metric Threads | 15 |

| Range of Metric Threads | 0.5 - 4 mm |

| Steady Rest Ability | 1-37/64" (40mm) |

| Follow Rest Ability | 1-37/64" (40mm) |

| Rated current | 14.4A/110V 7.2A/220V |

| AC Power Input | 110/220V, 1-phase, 60Hz (Prewired 110V,1-phase, 60Hz) |