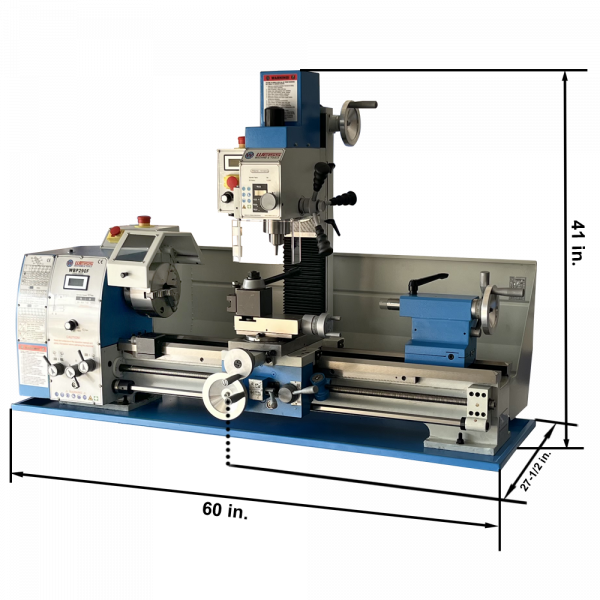

- WEISS WBP290F Lathe / Mill combination unit is an excellent choice for those who want to machine the parts without having to dedicate a large amount of shop space.

- WBP290F adds a variable-speed milling head to the lathe, giving you two versatile metal working machines in one. It fully equipped with work-holding and tool-holding equipment and accessories to get you started turning, drilling, milling, chambering, boring, and facing

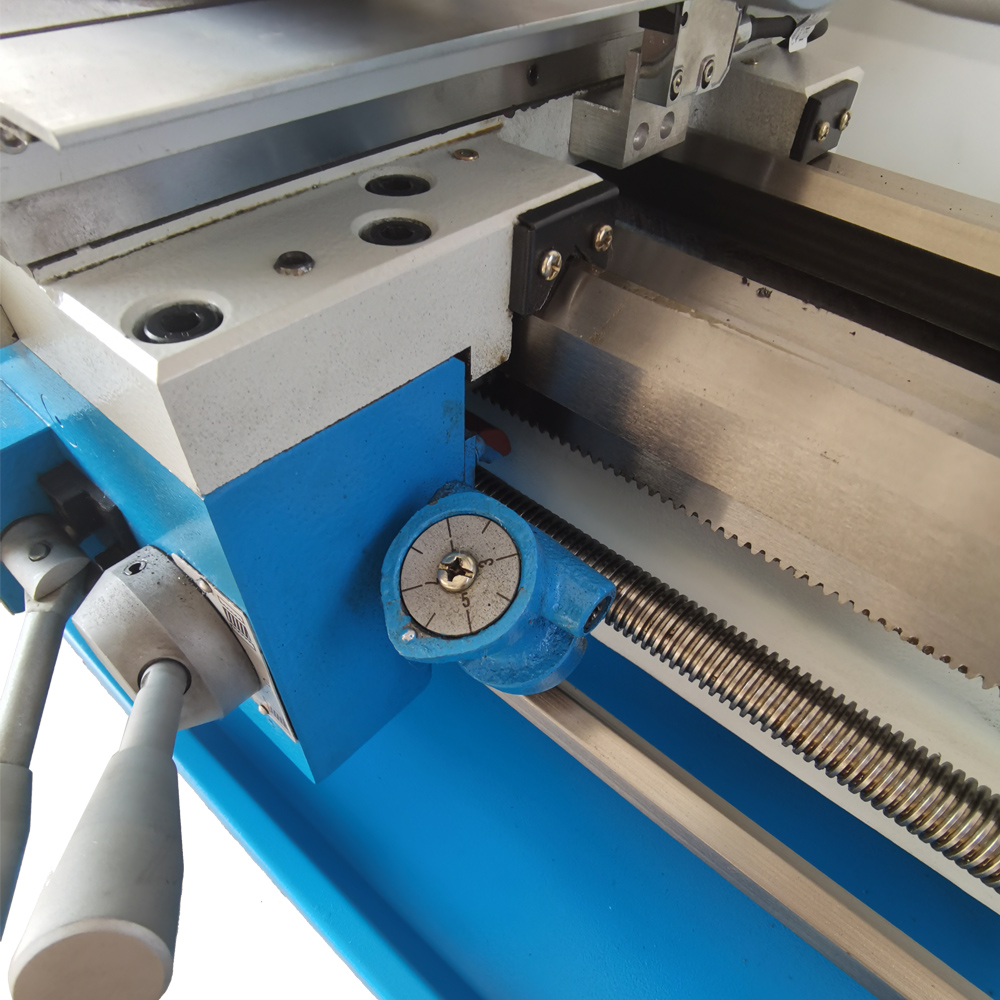

- Real inch leadscrew and all feed screws fo even, easy measurements. No need metric conversions

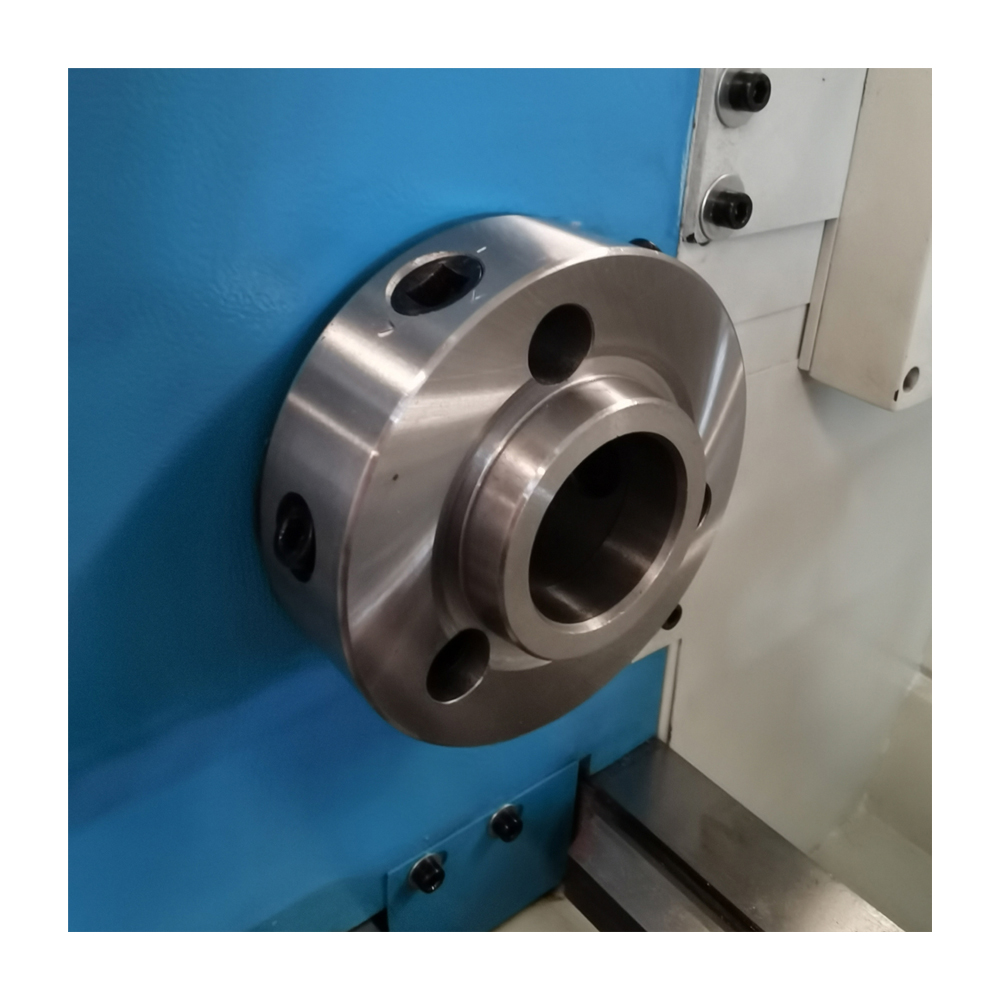

- D1-4 camlock spindle make swapping chucks a lot easier, more precision

- Large 1-1/2" spindle bore

- Power cross feed is available

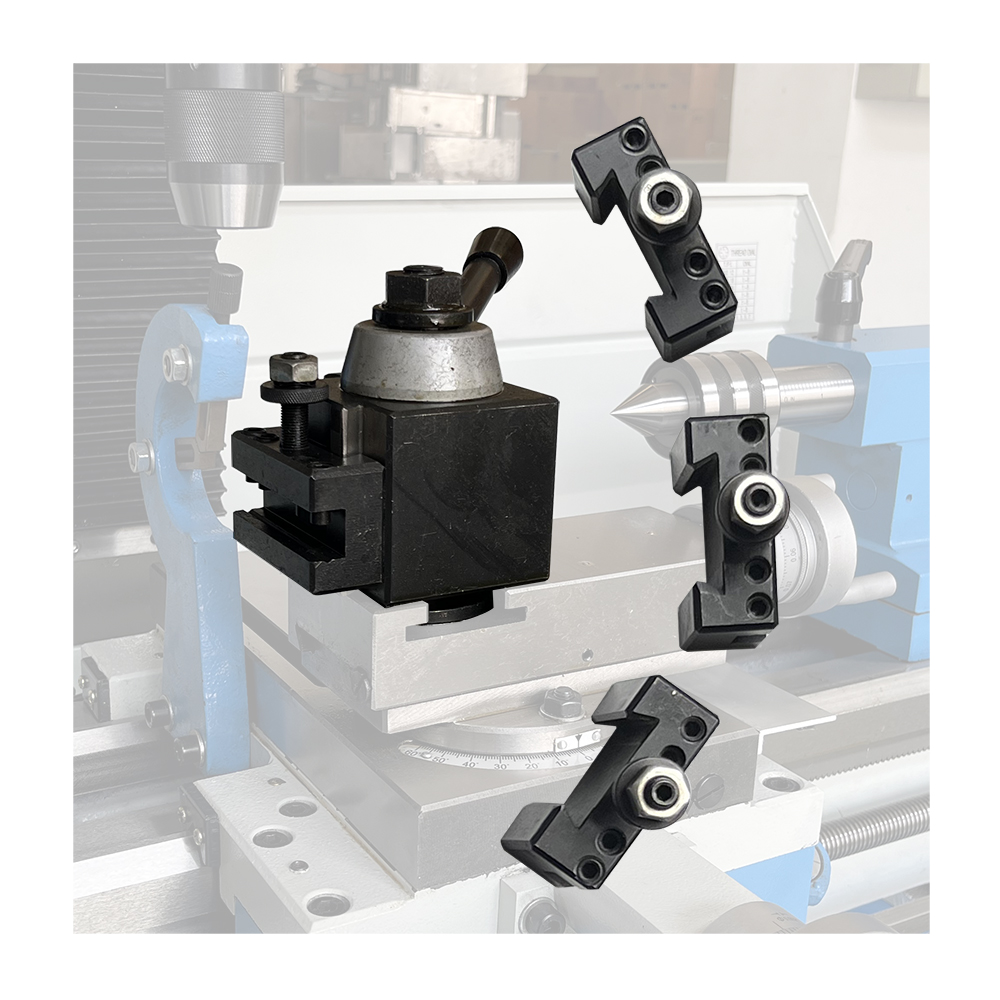

- Piston Type Quick Change Tool Post set included

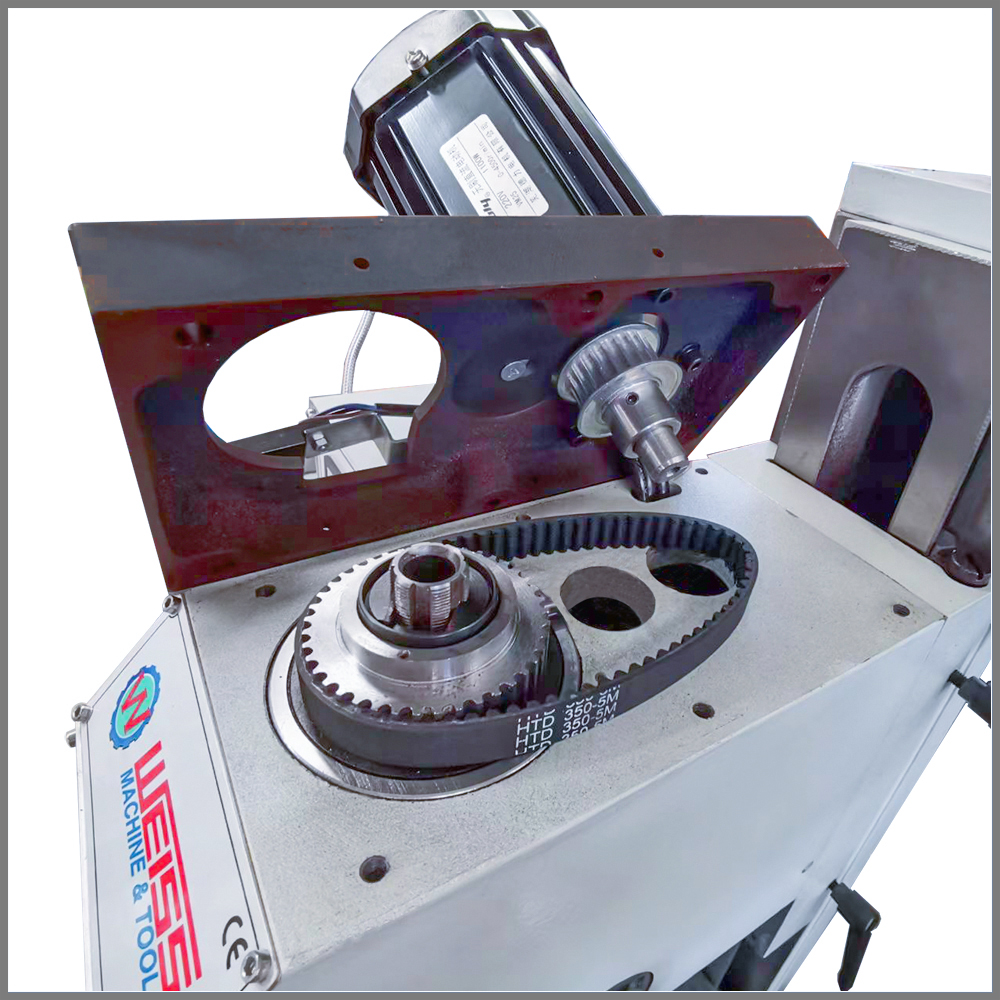

- Powerful brushless motors for both lathe&mill

- Rated at 110V, single phase, 60Hz input power

- WEISS factory provides reliable quality, in time service and fast technical support

Want TOP quality from China with best price? Come to WEISS, you will get the excellent value!

NEW features with steady rest, follow rest, faceplate, keyless chuck, MT3 living center & metal toolbox

Big Bore Spindle with MT#5 Taper

· Standard D1-4 Camlock Spindle which is dynamically balanced, harened and precision ground

· Spindle is supported by high precision, Class 5, adjustable tapered roller bearings

· Large 1-1/2" spindle bore

Electronic Driving System

· WBL290F has 2HP POWERFUL brushless motor for lathe and 1.5HP brushless motor for mill with silent running

· High quality electronics used throughout machine for long term reliability

· Braking resistors increase the stability of the electrical system

· Brushless motors has high efficiency, low noise (quiet), smooth operation, long life, low maintenance costs. Especially with low energy consumption brings better economic benefits to users

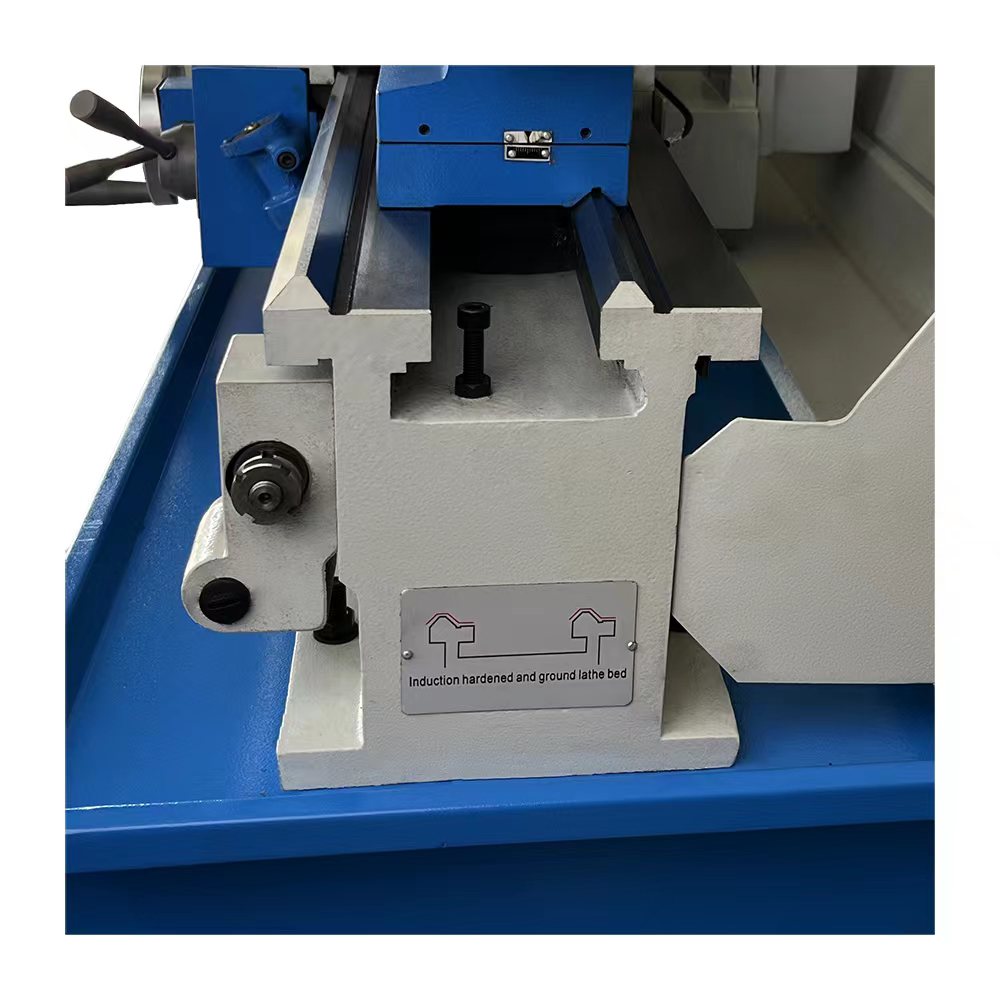

7" Heavy Duty Bed

· Heavy duty bed with 7" width same as most 12"x36" lathe

· Guideway induction hardened and precision ground for long life

Change Gears

· WBL290F change gears cover is equipped with protective QKS8 door swtich

· WBL290F change gears are all metal gears, can provides 21 kinds of inch threads and 12 kinds of metric threads cutting

· WBL290F gearbox provides both right and left hand threading

· Gearbox provides 3 kinds of feeding speeds

· Separate leadscrew and feed rod

Apron

· WBL290F apron can provide power cross & longitudinal feed

· Feed rod with clutch system and micrometer carriage stop provide more pretection

· Feed rod resistance power can be adjusted by the clutch

Tailstock

· WBP290F tailstock with quick lock handle

· Tailstock lock system features a drive hub to ensure consistent draw-down alignment every time

Piston Type quick change tool post

1x250-100, 3x250-101&1x250-102

Mill Attachment

· Variable speed enables to operate easily

· Spindle is supported by high precision taper roller bearing

· Spindle RPM can be monitored on the digital readout.

· Spindle movement can be monitored on depth ruler in both inch or metric way

· Single speed belt drive system provides more quiet and easy operation, avoid any failure prone plastic gears and the hassle of changing them when stripped (on old version mill)

· Tooth Belt provide strong and precision transmission

· Precision manual fine down feed can be adjusted with the min. feed rate up to 0.002"

· A clear chip guard with switch-off function on the spindle keeps debris from flying at the operator

Mill head can be tilted 90 degrees

One year warranty which covers parts and assures the unit from factory defects. Professional technical support from WEISS factory

WEISS, MAKE IT EASY!

LATHE SPECIFICATIONS

| Distance between centers: | 29" |

| Swing over bed | 11-1/2" |

| Swing over cross slide | 6-3/4" |

| Bed width | 7" |

| Spindle bore | 1-1/2" |

| Spindle nose | D1-4 |

| Spindle taper | MT#5 |

| Spindle speeds | 50-1800 RPM (Variable) |

| Motor type | Brushless, 2HP |

| Power supply | 110V/1Ph/60Hz |

| Rated current | 15A |

| Range of cross feeds | 0.0015-0.0056"/rev. |

| Range of longitudinal feeds | 0.0025-0.012"/rev. |

| Inch thread range | (21) 8–56 TPI |

| Metric thread range | (12) 0.4–3.mm |

| Cross slide travel | 6-3/4" |

| Compound rest travel | 3-3/4" |

| Tailstock taper | MT#3 |

| Tailstock quill diameter | 1-1/4" |

| Tailstock quill travel | 3-1/8" |

MILL SPECIFICATIONS

| Drilling capacity | 1" (steel) |

| End milling capacity | 5/8" |

| Spindle taper | R8 |

| Spindle travel | 2" |

| Spindle speeds | 50-2250 rpm (Variable) |

| Distance from spindle to table | 8-1/4" (w/guard) |

| Distance from spindle to bed | 11" (w/guard) |

| Head tilt | 45° Left/Right |

| T-slots | two at 3/8", 4-1/2" on center, 7" long |

| Drawbar | 7/16-16 TPI, 9-1/4" L |

| Motor type | Brushless, 1.5HP |

| Power supply | 110V/1Ph/60Hz |

| Rated current | 10A |

Packing Information

| Packing size: | 59" W × 29-1/2" D × 40" H |

| Approx. shipping weight | 780lbs. |

STANDARD EQUIPMENT:

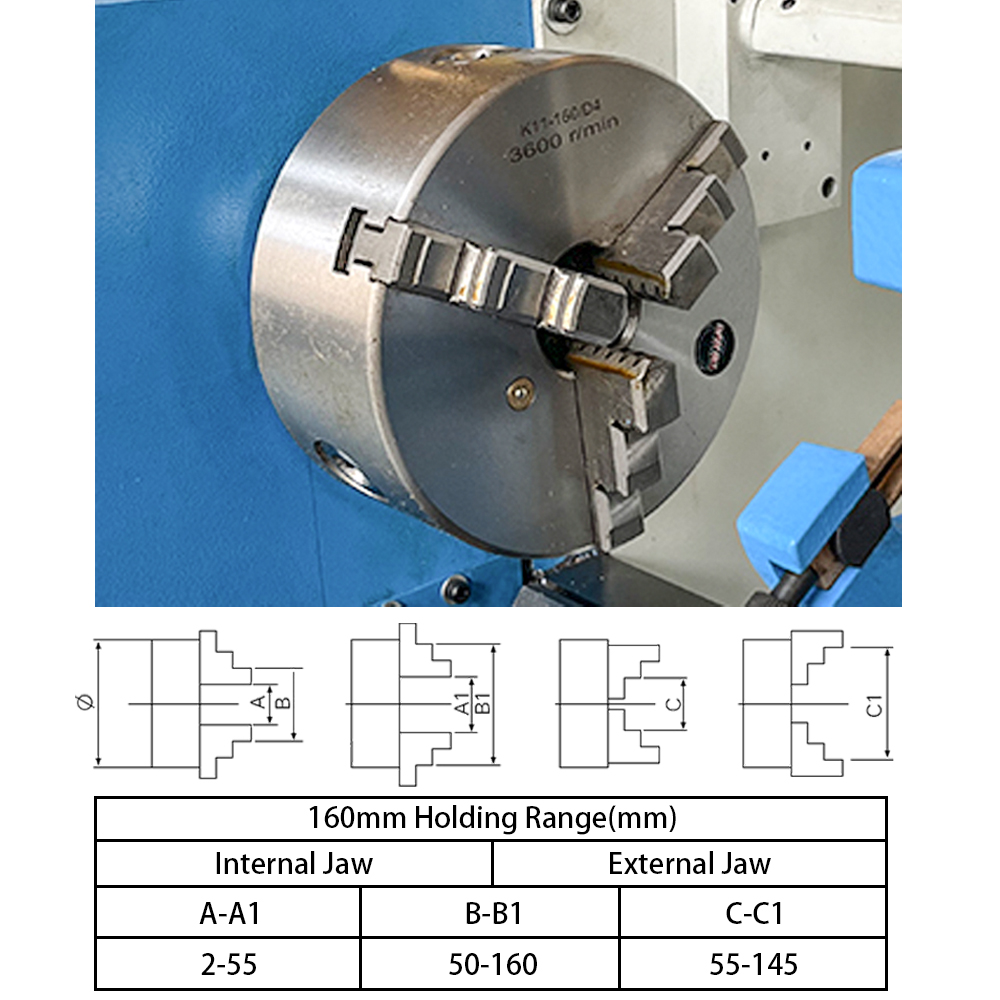

· 6" D type directly mounted 3-jaw chuck with two sets of jaws

· Steady rest

· Follow rest

· Face plate

· MT#3 dead centers and MT3/MT5 center sleeve

· MT#3 living center

· 250-111 Wedge type quick change tool post with 4 holders

· Chuck guard

· Splash guard & oil tray

· 5/8" JT33 keyless drill chuck

· Tool box with service tools

· Replacement fuse

Related Products

RPM320M led speed counter

$29.99