About this product

1. Compact structure and small volume

2. Quick maintenance, no disassembly of piping system

3. Symmetrical design can be realized, the flow of media can be reversed, not limited by the installation location, no positive and negative rotation points

4. Unique spiral rotor manufacturing, smooth pump operation, small pulse

5. Suitable for transport of shear sensitive fluids

6. Allow short dry runs

7. Can transport mixed medium of vapor, liquid and solid phase, with the function of warehouse sweeping

Introduction:

1. Made of by stainless steel 316 which conformed to the sanitry standard.

2. Used to transfer high viscosity liquids in various industrial fields:

Foodstuff: molasses, honey, yoghourt, chocolate, tomato sauce, syrup, fruit juice, cooking oil, edible oil, vegetable oil, cheese, protein, ketchup, sesame paste, mashed garlic, peanut butter, chilli sauce, etc.

Cosmetics: facial cleanser, shampoo, toothpaste, lotions, creams, liquid soap, shower gel, hairspray, etc.

Others: medicine, fertilizer solution, ceramic glaze, paint coating, etc.

3. Pump could be customized according to customers' requirements:

Vane type: single vane, double vane type, three vane type.

Connection mode: clamp, flange, Union, etc.

Motor type: CVT(Continuously Variable Transmission) motor, variable frequency motor, gear box motor, electromagnetic adjustable-speed motor, etc.

Moveable trolley for small model pumps.

Mechanical sealing water cooling device for high temperature liquids.

Heat preservation jacket for some mdiums which needs to be heated.

Twin-rotor lobe pump are multi-functional and bi-directional positive displacement pumps, produced with fine technology. The manufacturing engineering and precision of pumps approach the advanced level of the world.

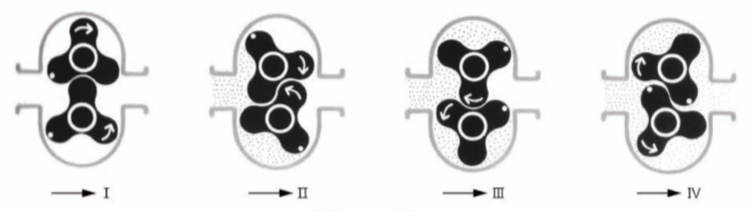

These products use synchronic rotors, driven by a pair of synchronic gears in the gear box. Transmitted by the main shaft and the sub-shaft. The rotors move synchronically in counter-clockwise directions, which, consequently, varies the pump capacity and builds up high vacuum capacity and emission pressure. It is particularly suitable for the pumping of sanitary medium, high-corrosive and high-viscous medium.

These products consist of two series: sanitary type and corrosive resistance type in structure they fall into two varieties: high pressure with high viscosity and high pressure with low viscosity. The core parts and sealing devices of the products are made of different materials and sealing methods, based on the properties of different medium. These special designs greatly help the transmission performance of the pumps.

The products can be widely used in petrochemical industry, fine chemistry, consumer industry, pharmaceutical industry, foodstuff industry, environmental protection, paper-making, chemical fiber, painting, metallurgy, oil field and so on.

| Type | 40HT5A-12 |

| Capacity (L/r) | 0.32 |

| Rotation (r/min) | 10-500 |

| Flow (GPH) | 1320 |

| Pressure (Mpa) | 0.1-1.2 |

| Power (HP) | 1/2 - 4 |

| Suction pressure (Mpa) | 0.08 |

| Exit pressure (Mpa) | 1.2 |

| Viscosity (cp) | 1-1000000 |

| Inlet & outlet DN (inch) | 1-37/64 |